Sustainability meets fire protection: With the new generation of the Loctite HB adhesives, Henkel is setting a benchmark for environmentally conscious and safe construction. The Loctite HB XE Line is the consistent further development of the proven Loctite HB polyurethane adhesives, which have been successfully used in timber construction for over 30 years. As fire protection requirements have increased in recent years, Henkel now has developed the Loctite HB XE Line: It meets the highest fire protection requirements, addressing the growing importance of fire resistance in European timber buildings.

Loctite HB XE is a high-performance structural adhesive specifically designed for the surface bonding of cross-laminated timber (CLT) and glued laminated timber (GLT). With this new generation, Henkel is setting new benchmarks in fire protection and promoting climate-conscious and sustainable timber construction across Europe.

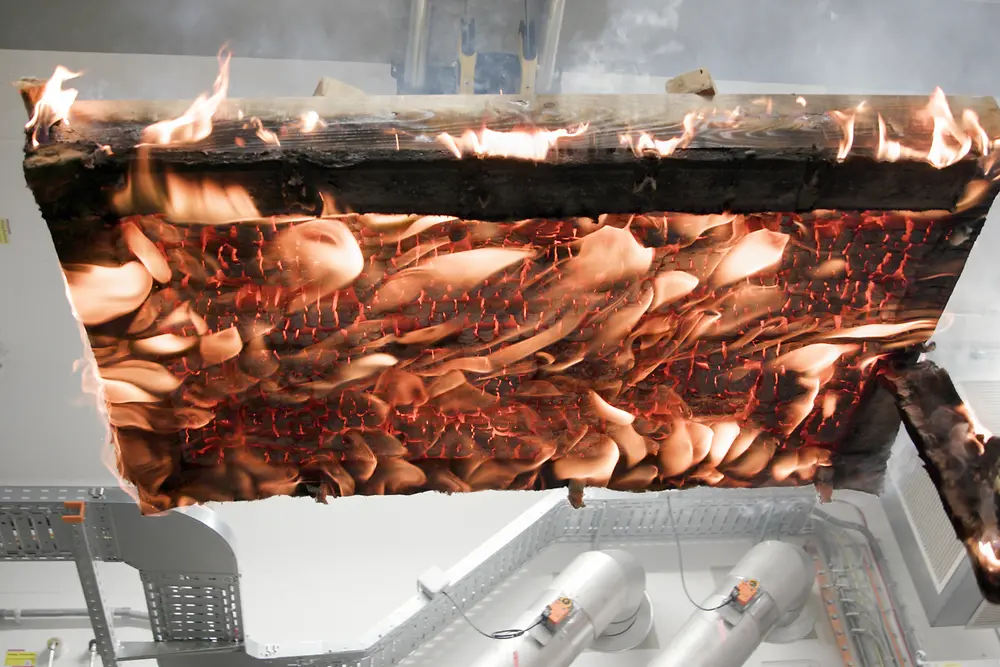

Successful laboratory testing

The Loctite HB XE Line meets the highest fire protection requirements in accordance with Eurocode 5 (EC5). It has been proven to exhibit a linear charring rate of 0.65 mm/min, which corresponds to the burn rate of unbonded wood. Compared to traditional adhesives for CLT or GLT, the burn rate slows down, eliminating the risk of a ‘second flashover’ and creating the conditions necessary for the self-extinguishing of a building's wooden components.

In the fire simulator at ETH Zurich, the new adhesive demonstrated its excellent fire protection capabilities. By using the Loctite HB XE Line the design possibilities for architects and structural engineers can be expanded. They now can realize taller buildings with slender cross-sections while optimizing the use of timber as a material.

According to EC5, the fire test successfully passed by Henkel (‘Glue Line Integrity in Fire (GLIF) maintained’) can be applied to CLT and GLT components by users, eliminating the need for additional fire tests.

The Loctite HB XE Line also scores highly in terms of sustainability: All its components comply with stringent health and safety standards for construction products and are free of substances listed on various sustainability certification restricted substance lists, such as the Nordic Swan Ecolabel.

Increased efficiency in manufacturing

The innovative adhesive in addition optimizes production processes: The combination of reduced open time and press time in the highly catalyzed products of the line enables quick and precise application. Another advantage is its seamless integration into existing production workflows.

Olga Golgor, Head of Sales Europe for Engineered Wood at Henkel Adhesive Technologies, is convinced: “With the Loctite HB XE Line, we are setting a new standard in both fire protection and sustainability for the European timber construction market. This product line is the ideal choice for CLT and GLT manufacturers who want to combine high safety standards with efficient production. A true advancement for the future of timber construction.”

For large-scale projects such as the Skypark in Luxembourg, where the proven predecessor Loctite HB X was used, Henkel now offers a fire- and heat-resistant solution with the new Loctite HB XE Line which increases the possibilities for architects and engineers in planning and realizing sustainable timber buildings.