Advance circularity through our products, packaging and technologies.

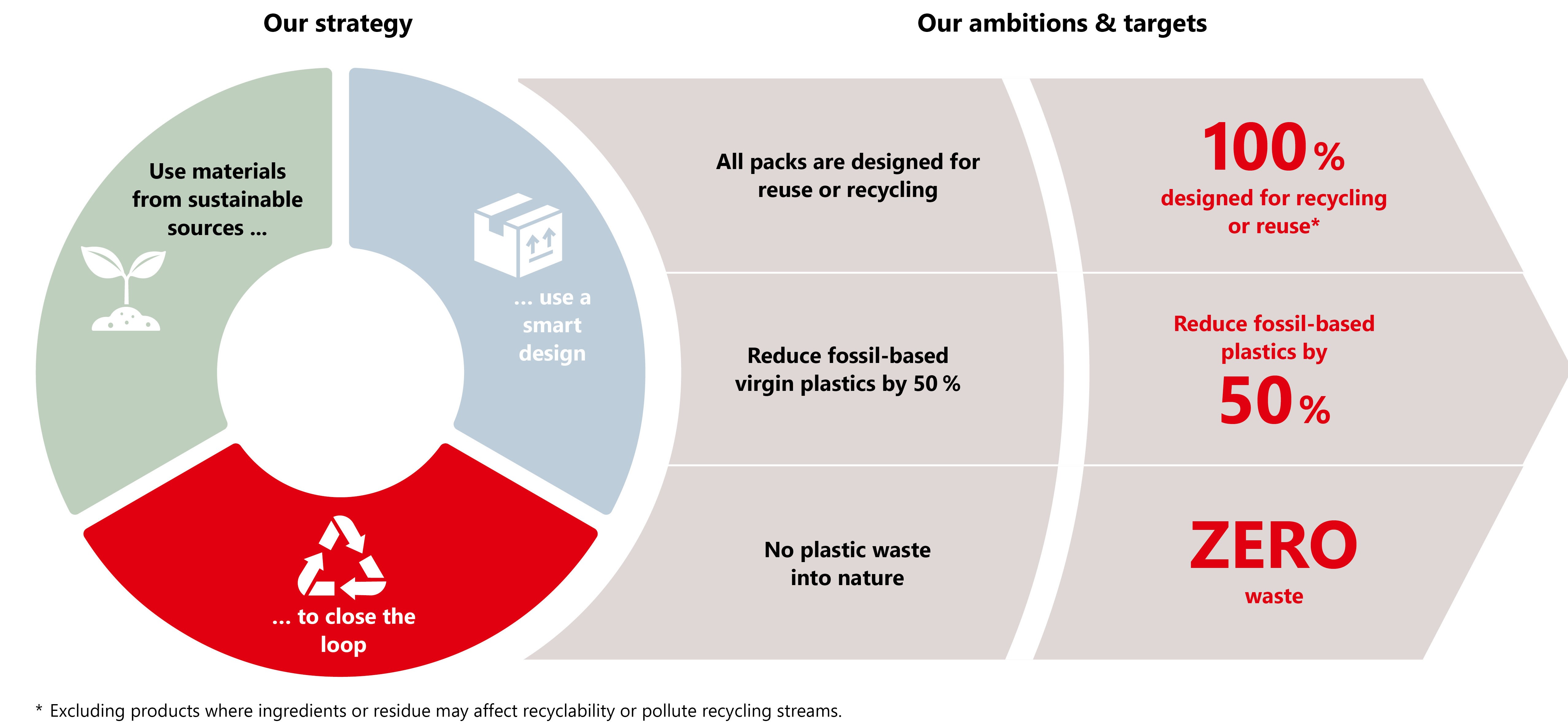

Our ambitions & targets for packaging

By the end of 2024, 89 percent of Henkel's packaging was already designed for recycling or reuse*. The proportion of recycled plastic in its consumer goods packaging was 25 percent globally.

Initiatives and partnerships

Progress towards sustainability in packaging is only possible if companies along the entire value chain work together. Therefore, Henkel is engaged in various partnerships and cross-industry initiatives. A few examples:

- We participate in the New Plastics Economy initiative of the Ellen MacArthur Foundation, which brings together stakeholders to rethink the future of plastics and provide ideas to foster a circular economy.

- In the Plastic Waste Coalition of Action, which was formed from the Consumer Goods Forum (CGF) in 2020, Henkel is working with other companies on the basis of Golden Design Rules to develop a more circular approach to the design and processing of plastic packaging in the consumer goods industry.

- Henkel is also an active supporter of the "Business Coalition for a Global Plastics Treaty" of the UN Treaty on Plastic Pollution. Together with more than 170 other global companies, we are in a multi-stakeholder process for a global agreement on the sustainable use, recovery and recycling of plastics.

Nature

Protect and restore biodiversity with a focus on forests, land and water, and ensure responsible resource stewardship:

- We are committed to sourcing our raw materials sustainably and not through deforestation. Our goal is to prevent the deforestation of primary and secondary forests with significant ecological value.

- One of our palm oil targets by 2025 is to cover 100 percent of our requirements with oils whose responsible sourcing is certified or externally confirmed. In fiscal year 2024, we sourced 97 percent of our total demand for palm oil and palm kernel oil as well as the derivatives, which are primarily used by Henkel, as certified raw materials in accordance with the RSPO mass balance model.

- In addition, we have set ourselves the goal of reducing water withdrawal per ton of product by 35 percent by 2025. By the end of 2024, we had saved 23 percent.