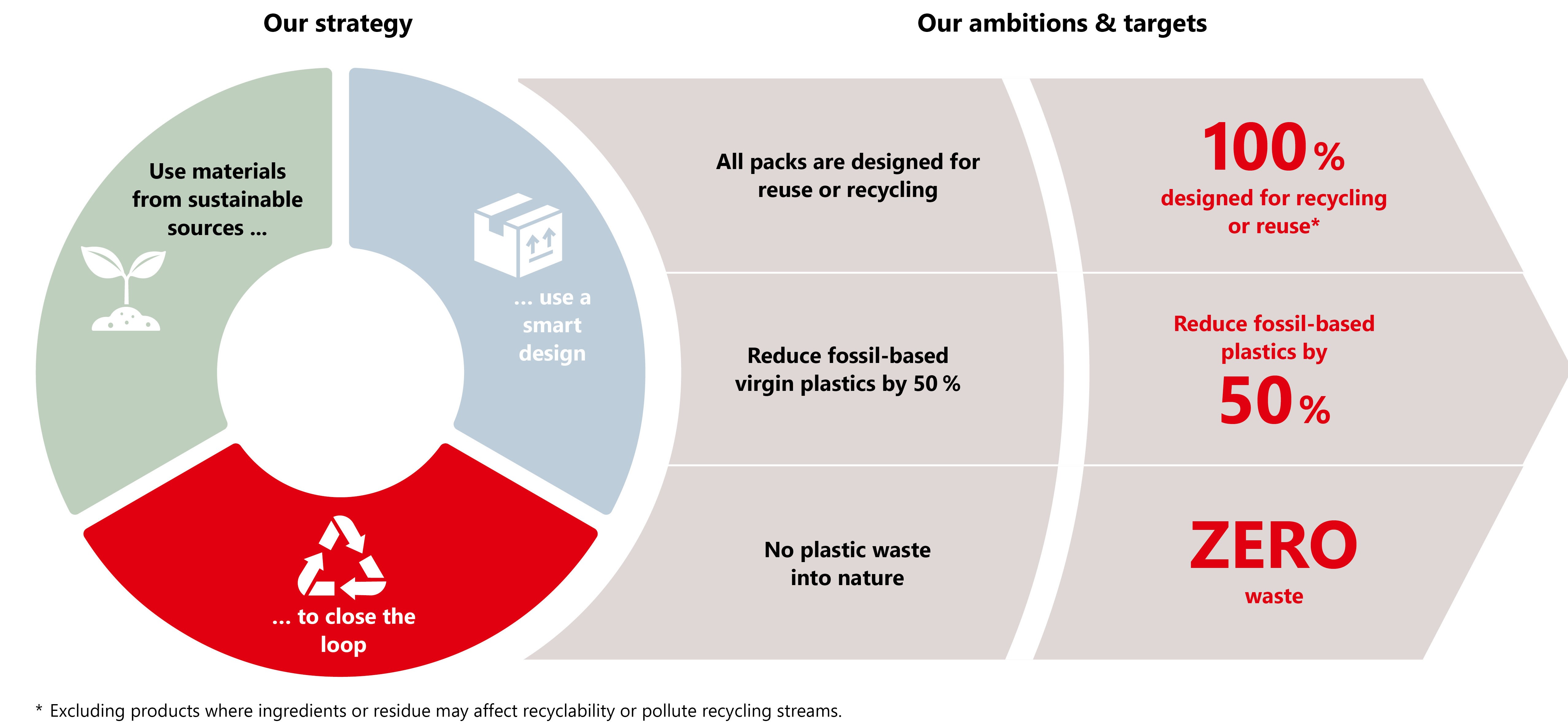

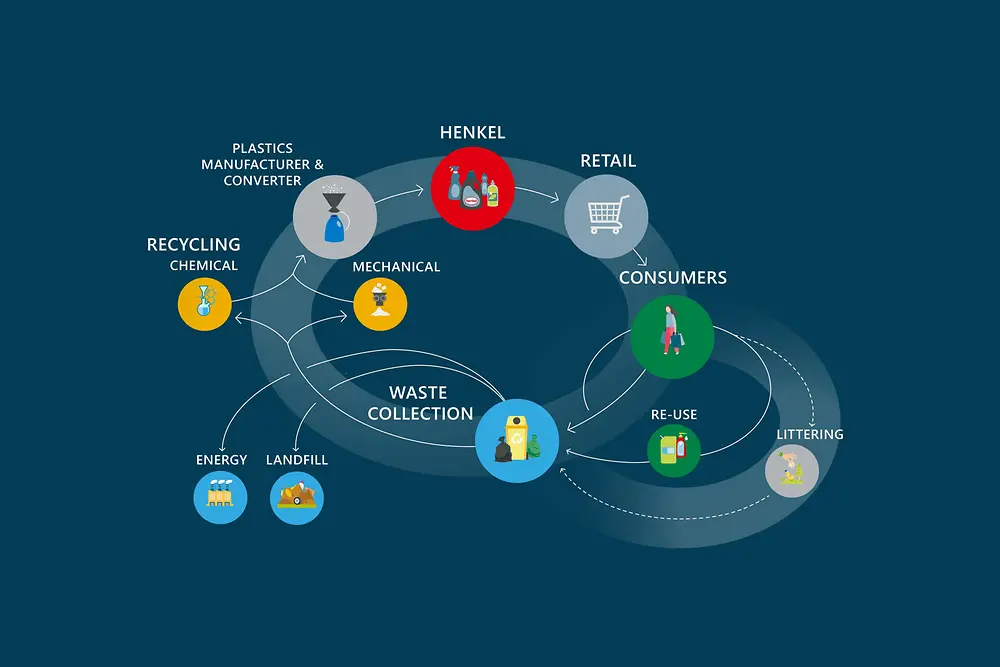

Eliminating, reducing and – where this is not possible – recycling packaging materials, especially for our consumer goods, is the best way to minimize waste and the related negative environmental effects. Our goal is to reduce the amount of packaging material we use to a minimum – without compromising the quality, performance or safety of our products – and to provide consumers with all the information they need for safe use and proper disposal. With a few exceptions, today our packaging has been developed to provide the level of performance consumers expect, while minimizing the use of resources. In addition, our packaging can be disposed of in existing collection and recycling systems.

At the same time, resource consumption can be reduced if materials are kept within the cycles of the economy for as long as possible. As a result, our mission is to include materials from sustainable sources and to design packaging so that it can be reused as raw materials for new products in order to close the material loop. Our packaging developers work closely with suppliers, packaging material manufacturers, recyclers and reprocessors to meet the requirements of functional packaging.

In our Adhesive Technologies business unit, we are focusing on innovative solutions that facilitate recycling and on the separation of materials to make it possible to repair, reuse and refurbish products and product parts.

Henkel is also pursuing a variety of approaches to implement closed-loop recycling in its own production processes. In this area, we emphasize the separate collection of all recyclable waste streams at our sites.

Our new Circularity Policy describes Henkel's ambitions, goals and measures in the area of circular economy.