Did you know that Henkel North America employs over 8,000 employees in approximately 60 sites across the U.S., Canada and Puerto Rico? Collectively, these sites support three business units: Adhesive Technologies, Beauty Care and Laundry & Home Care.

Our #AViewFrom series features select locations, sharing information and facts about our sites across Henkel North America.

Whether a commercial aircraft, a small satellite, a helicopter, or a rocket, the products made by Henkel’s Bay Point, CA staff of nearly 300 contribute to the safety, comfort and efficiency of modern flight vehicles. Made up of three production units containing mixing, converting, and packaging lines, the Bay Point site operates around the clock to manufacture a variety of bonding adhesives found throughout air and spacecraft – from the interior cabin structures to the engine and wings.

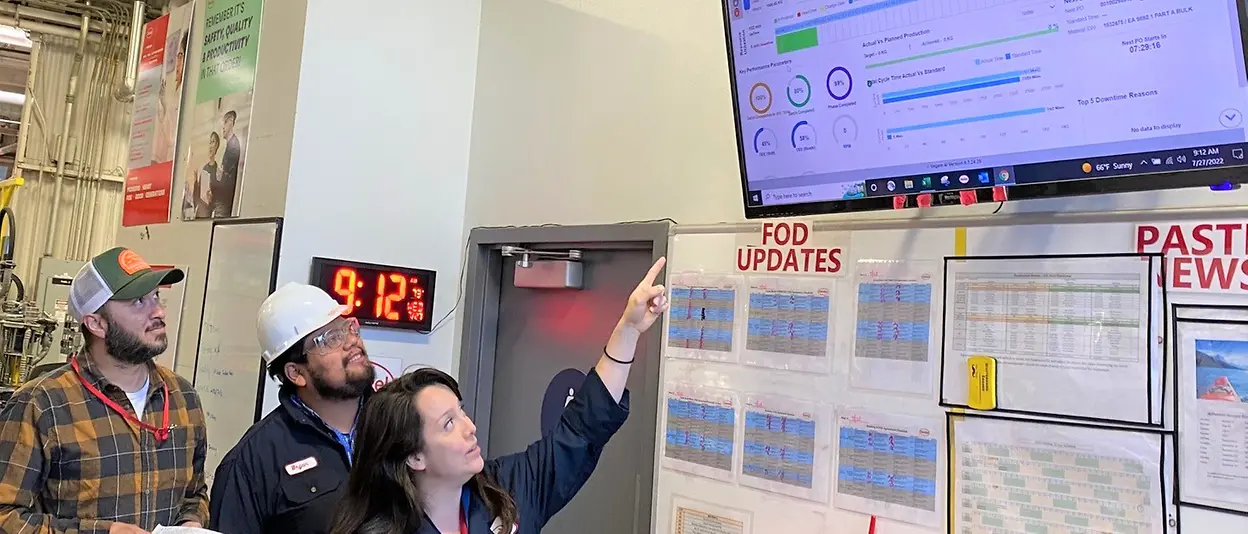

“The team here appreciates the critical nature of our work and the impact it has on people’s lives,” says Human Resources Manager Dan Cahill. “There is no room for error, no acceptable risk; our products must be top quality, within spec, and of the utmost integrity 100 percent of the time. I’ve never worked with a group of people more invested in and focused on their mission. It’s remarkable.”

![Aircraft collage slideshow]()

Henkel’s team at the Bay Point, California facility manufactures a variety of adhesives under the Loctite® brand. These products are used in commercial airplanes, helicopters, rockets, miliary aircraft and other applications to support the aerospace industry.

Acquired by Henkel in 2000 from Dexter Hysol Aerospace, the 117,000 sq. ft. Bay Point facility sits on over 12 acres in Northern California, and is currently transforming its operations to deliver real-time, data-driven results with its smart factory initiative.