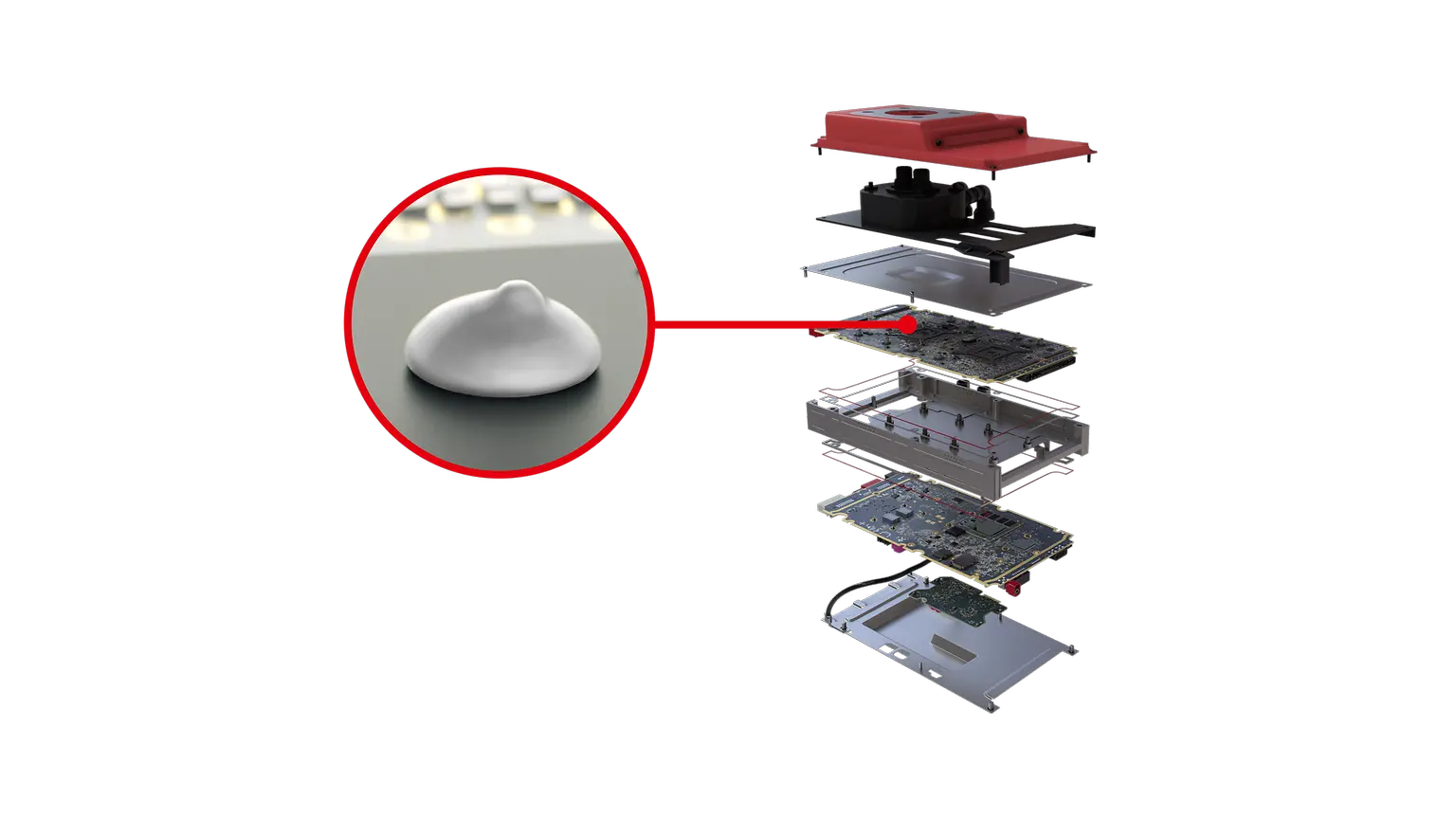

To anticipate this challenge, Henkel has developed Berquist Liqui Form TLF 6500 CGel-SF, an upgraded thermal curable gel designed to push the envelope of ADAS applications. By delivering a higher level of conductivity it works to prevent performance degradation and protect sensitive electronic assemblies.

Berquist Liqui Form TLF 6500 CGel-SF is a new thermal management material with a conductivity of 6.5W/(m·K). With its lasting reliability, easier handling and optimal sustainability it meets growing demand for superior heat dissipation solutions to protect ADAS components and vehicle computing units from heat degradation and damage.

“As safety standards and OEM and driver expectations evolve, ADAS systems are becoming ever more sophisticated. This makes it vital to effectively manage the heat generated by domain controllers to ensure their long-term reliability. Our top OEM partners, for example, are launching a high-intelligence vehicle platform which needs to process up to 4.5 terabytes of data per hour. This fivefold increase of data generates high heat concentration, requiring more effective thermal solutions to avoid component failure,” explains Nancy Yang, Business Development Manager for Automotive Electronics North America at Henkel. “Additionally, the sensitive and fragile nature of these components requires a solution that can be applied with low stress to avoid damage. As part of Henkel’s upgraded range of thermal management materials, Bergquist Liqui Form TLF 6500 CGel-SF has been specifically engineered to address this breadth of challenges.”

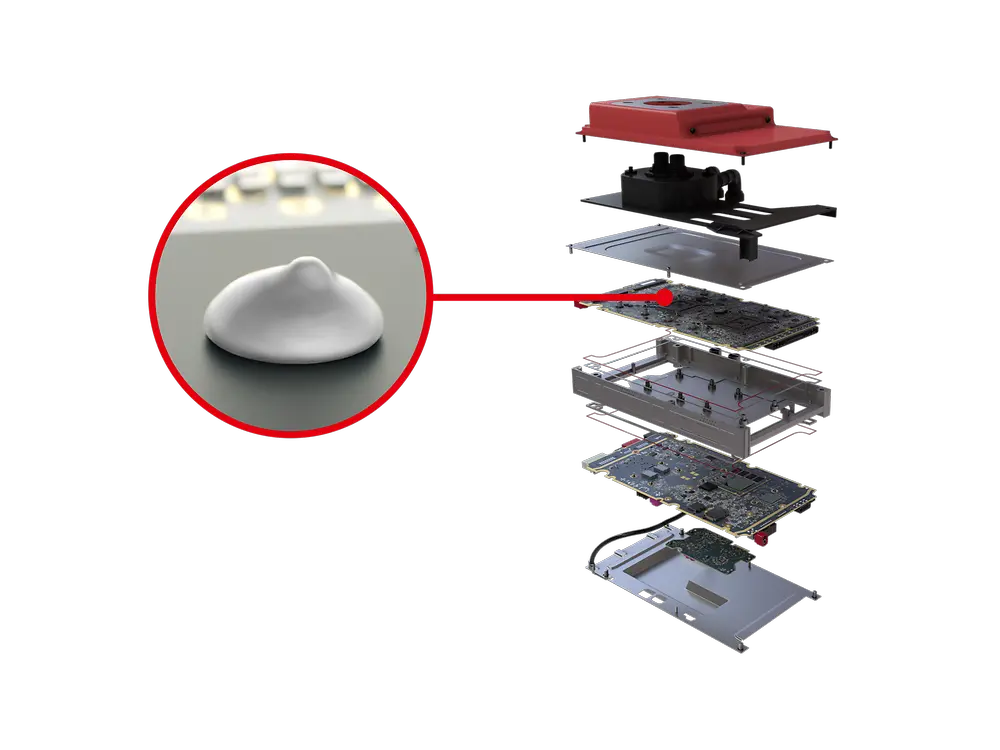

Bergquist Liqui Form TLF 6500 CGel-SF is a one-part, silicone free, easy-to-dispense thermal curable gel. With an exceptional conductivity rating of up to 6.5W/(m·K), the gel delivers superior heat dissipation for components managing heavy data loads. As a cured elastomer, it offers ultra-low compression stress to protect fragile assemblies and sensitive electronic components and effectively fills air voids and irregular gaps to ensure even heat transfer across the surface.

The new product has been designed to enhance production efficiency. It can be dispensed at high speed to match with just in time manufacture processing. Meanwhile, Bergquist Liqui Form TLF 6500 CGel-SF provides excellent reliability and avoids any cracking or thermal failure during thermal cycling and therefore effectively expands component lifespan.

Bergquist Liqui Form TLF 6500 CGel-SF has been designed in alignment with Henkel’s goals for sustainability. It is a low VOC product which is D4-D10-free. It protects operators at the production line as well as avoids any fogging issues for components with lenses such as cameras. It is an extremely low oil bleeding thermal solution which suits applications for sensitive components including radar/lidar.