“From modeling and simulation solutions that significantly accelerate the development of EV batteries, to full-scale battery system testing, Henkel is constantly innovating solutions that will make EVs safer and more affordable,” explains Frank Kerstan, Head of E-Mobility Europe at Henkel.

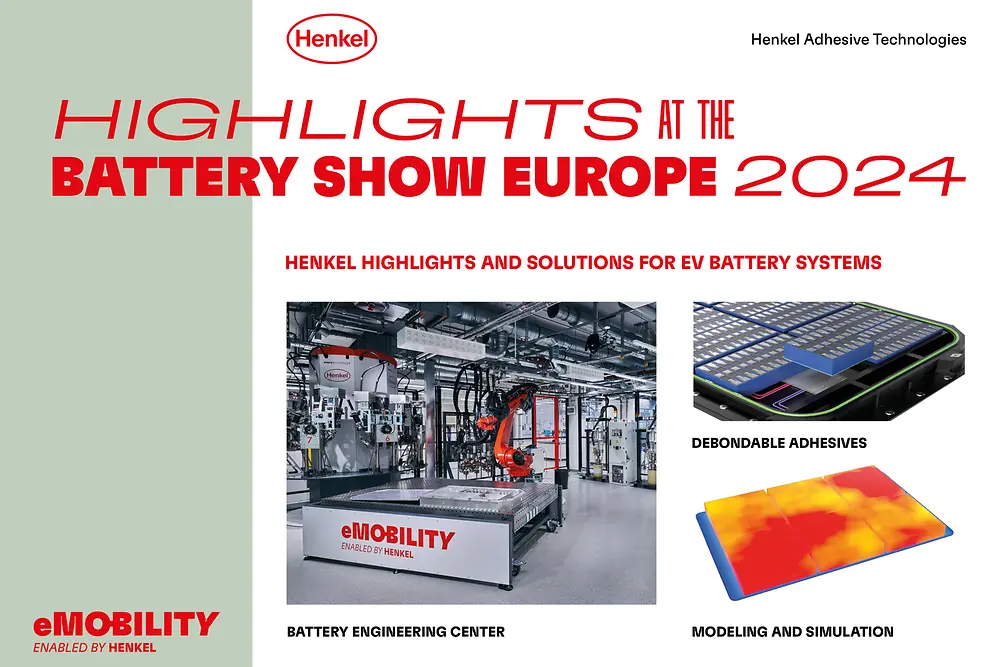

Key innovations presented by Henkel at the Battery Show Europe include new debondable adhesives that enable the circularity of batteries, by facilitating repair, re-use, and recyclability. “High energy density battery designs, such as cell-to-pack designs, require high structural integrity of the battery cells into the battery tray or even the car structure. With this in mind, debonding technology becomes vital to enable the repair, reuse, and recyclability of the battery,” adds Dr. Olaf Lammerschop, Global Technology Lead for E-Mobility at Henkel.

Henkel will also present its latest modeling and simulation capabilities that help customers and partners accelerate their product development timelines. “We are significantly reducing product launch times by leveraging our state-of-the-art battery simulation and testing capabilities,” comments Dr. Keon Lee, Senior Manager Product Development, Battery Solutions at Henkel. “Most notably, we recently opened our new Battery Engineering Center in Düsseldorf, a ground-breaking facility where we offer our customers modeling and simulation services, automated material dispensing, and full-scale battery system testing. These unique capabilities help our customers improve the safety, performance and quality of cost-effective next generation EV batteries.”

The Henkel booth will host a live showcase on Tuesday, June 18, 2024, at 11:30 AM around the new Battery Engineering Center and its capabilities.

Alongside the latest innovations and capabilities, Henkel’s exhibition booth provides visitors with the opportunity to meet with Henkel experts and discover the broad portfolio of solutions, tailored to optimizing the design, assembly and sustainability of EV batteries. This includes: