“Loctite Ablestik ICP 2120 demonstrates the power of Henkel’s broad technology toolbox,” comments Electronics Product Development Director Toshiki Natori, noting the formulation expertise required to deliver on multiple metrics. “Many ECA materials are solvent cure adhesives that require high temperature to fully cure. Loctite Ablestik ICP 2120 uses a unique chemistry platform, creatively engineered through Henkel’s scientific know-how, to satisfy demanding mass production and performance requirements.”

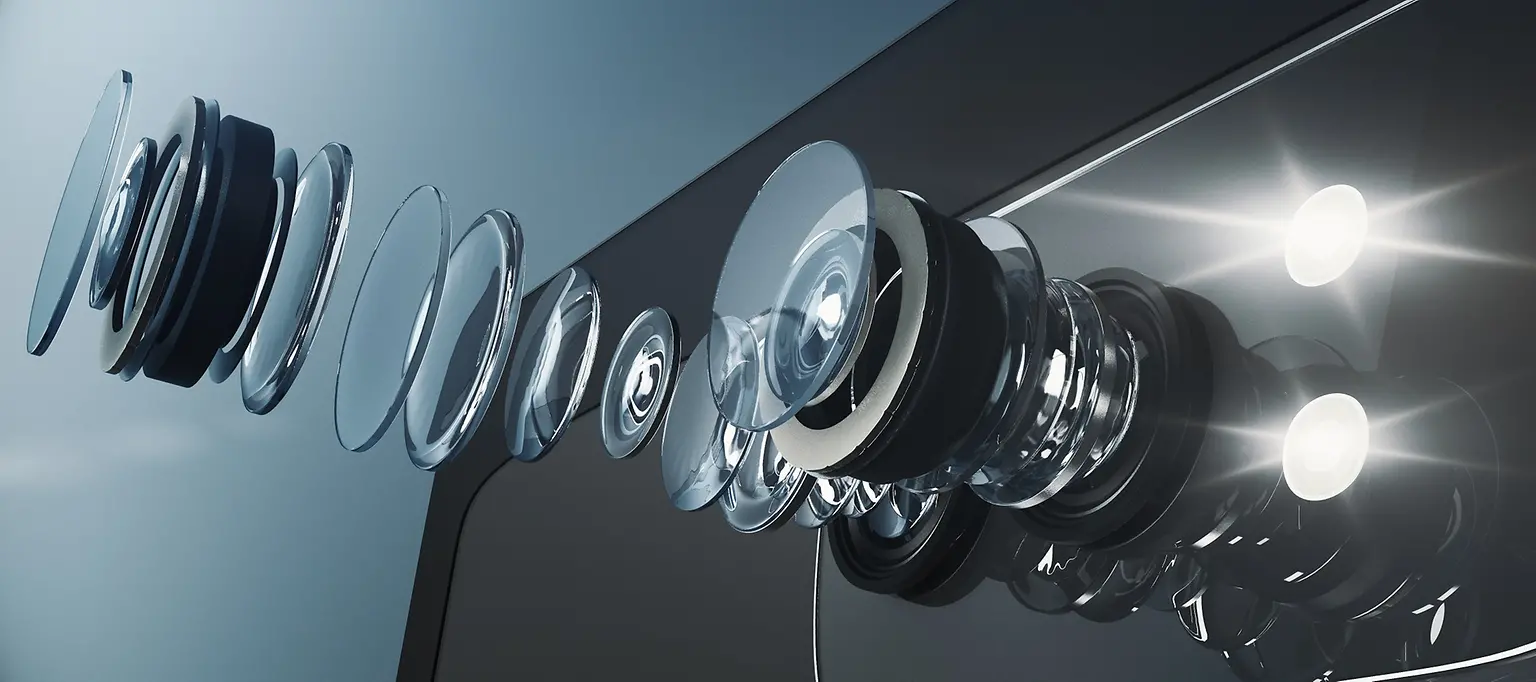

In addition to its core electrical advantages, Loctite Ablestik ICP 2120’s distinctive chemistry provides a low modulus (900 MPa @ 25°C) to ensure better drop performance, as well as a curing profile for fast room- or low-temperature (50°C for 30 mins.) cure to enable high volume processing, substrate protection and reduced energy consumption. Excessive heating of smaller, thinner, more complex CCM substrates can cause them to warp or shrink, impacting optical performance and decreasing yield, so limiting high-temperature exposure is essential.

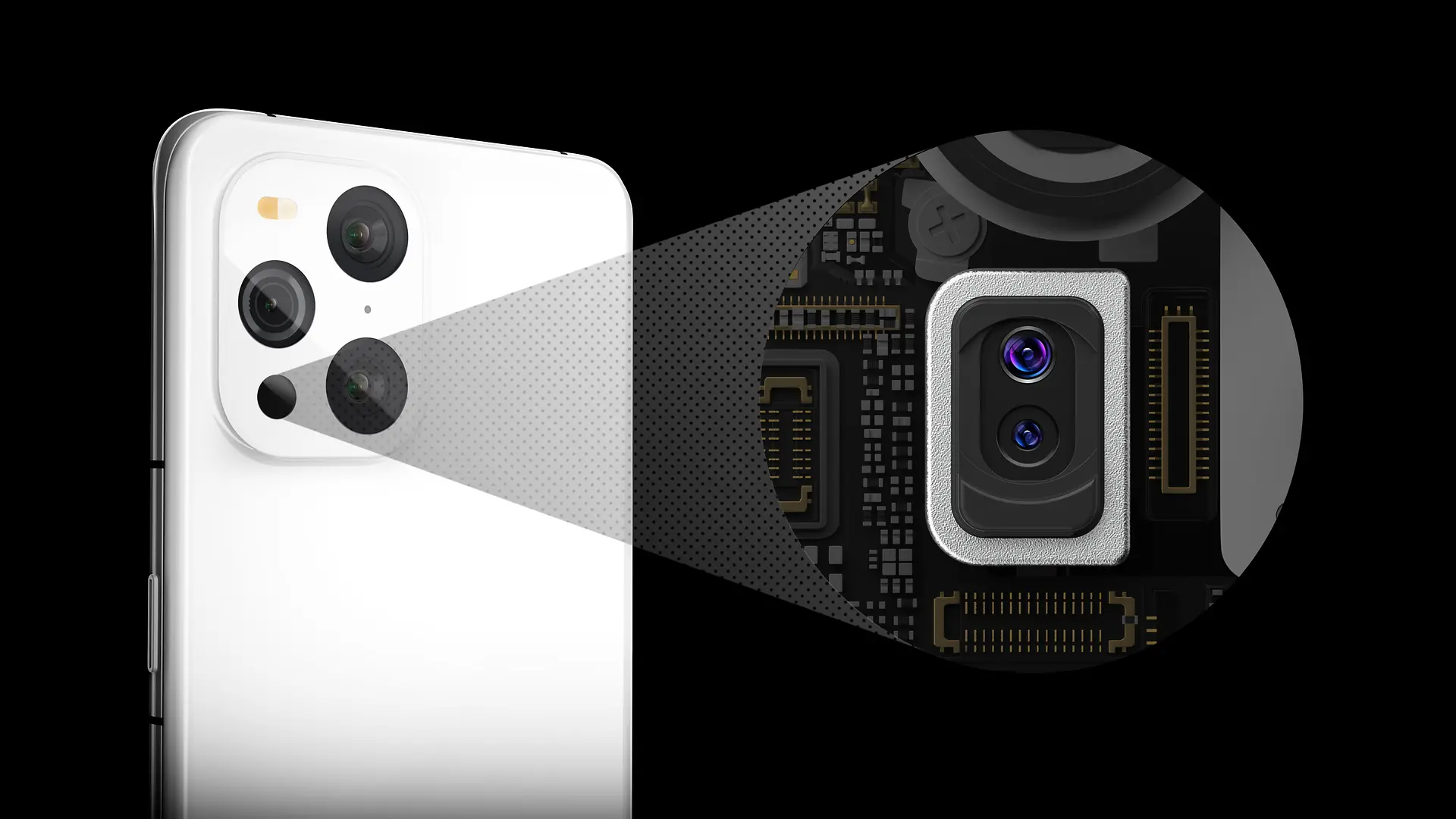

Importantly, as Loctite Ablestik ICP 2120 is designed for electrical grounding, its electrical properties have been optimized for excellent performance. The material has low direct contact resistance (DCR @<5Ω/piece) as demonstrated on customer modules, and low volume resistance to ensure thorough removal of electrostatic discharge from the substrate for robust operation. In addition, with CCM functionality expanding while footprints remain comparatively small, heat generation may also be a concern. Loctite Ablestik ICP 2120, which has a high thermal conductivity of 7.0 W/m-K, helps dissipate operational heat to improve performance and reliability.

While initially developed for CCM multi-camera applications, Loctite Ablestik ICP 2120’s characteristics may also be beneficial for other ECA applications, such as OLED display grounding or device-level EMI shielding, for example. As Natori says in summary, “The attributes of this ECA are quite distinct, allowing excellent electrical performance while protecting the delicate nature of many heat-sensitive miniaturized components and ensuring compatibility with high-volume production environments. This is a rare combination of properties and a notable advantage for mobile device designers.”