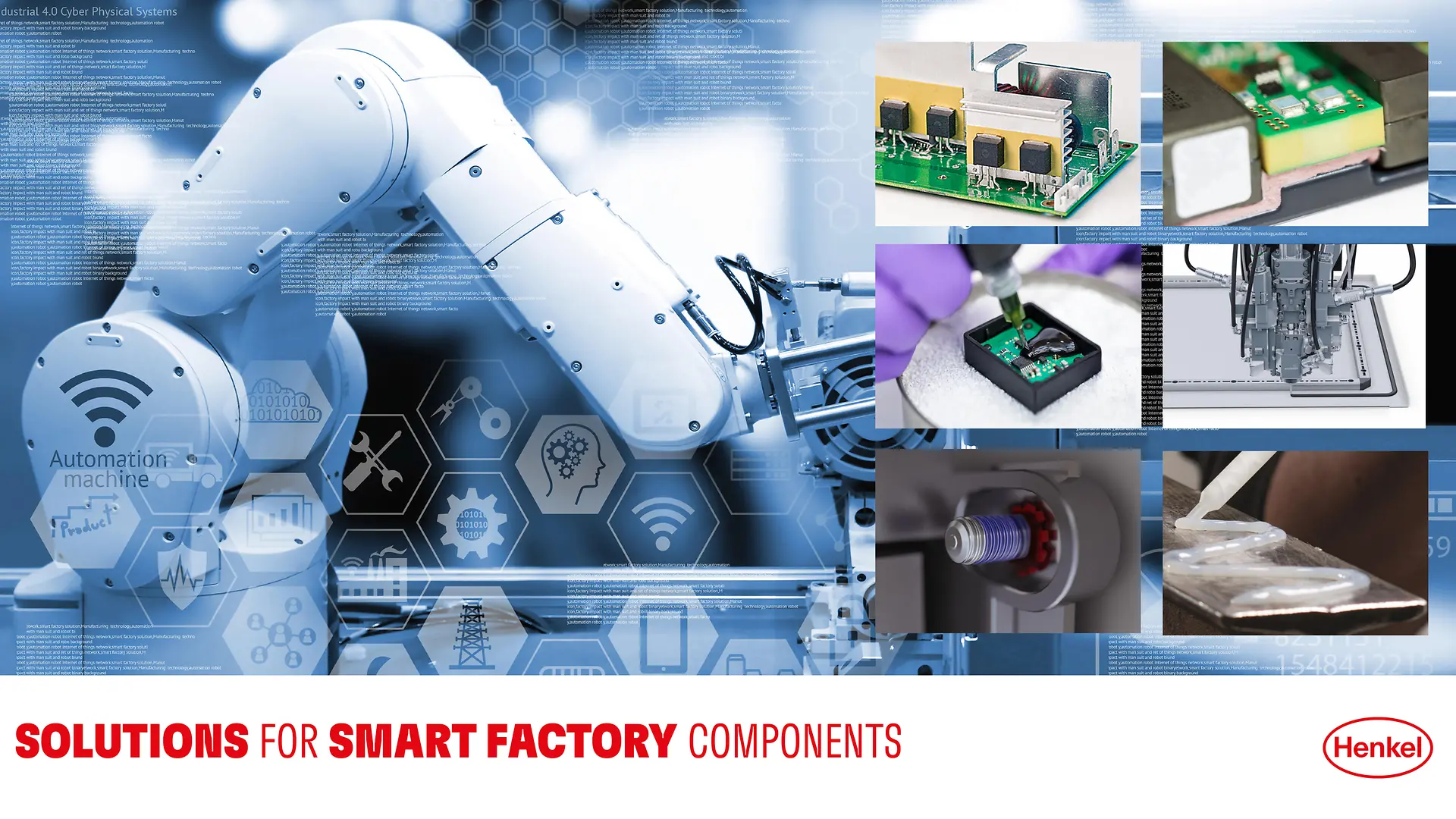

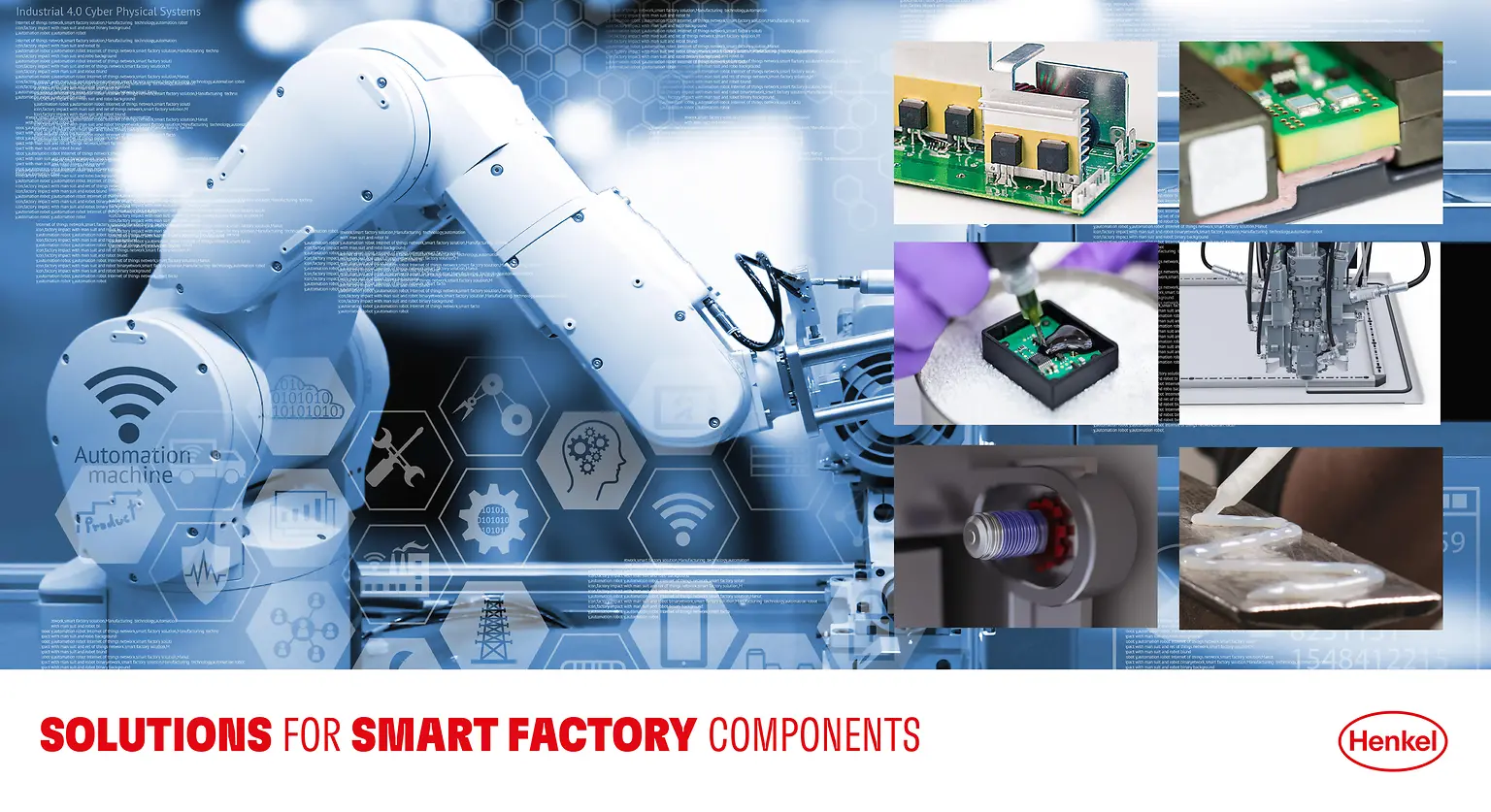

The operational demands of more complex machine-to-machine communication (M2M) systems, advanced robotics, and factory energy management networks require high-performance thermal control and electronic protection materials. Integrating system-enhancing materials helps reduce manufacturing downtime, lower cost and extend viable hardware life through improved reliability. Among Henkel’s proven products are:

“The demonstrable quality and efficiency benefits of artificial intelligence (AI) and machine learning within the smart factory are well-documented. I4.0’s successful evolution, however, requires innovations that can address the intersecting expectations of form, function, cost, efficiency, and reliability – all while digitized production systems incorporate higher-power devices to support big data and continuous operation,” says Henkel Director of Market Strategy for Power and Industrial Automation, Justin Kolbe. “We are partnered with the world’s leading developers of energy generation and power conversion systems, motors and drives, and controllers and sensors that make factories of the future possible.”

Recent examples of tangible results include:

Kolbe underscores the importance of Henkel’s ingenuity in the I4.0 space, acknowledging the central role of data control and analytics, while highlighting the absolute requirement for high-performing mechanical systems. “Motors, drives, controllers and robotics are the muscle executing on smart factory’s intelligence,” he says. “For true lights-out automation to transpire, bits and bytes must be supported by dependable, high-performance brawn. That’s what Henkel materials deliver.”

Learn more by visiting Henkel’s online resources.

Watch a video – Trends driving Industrial Automation