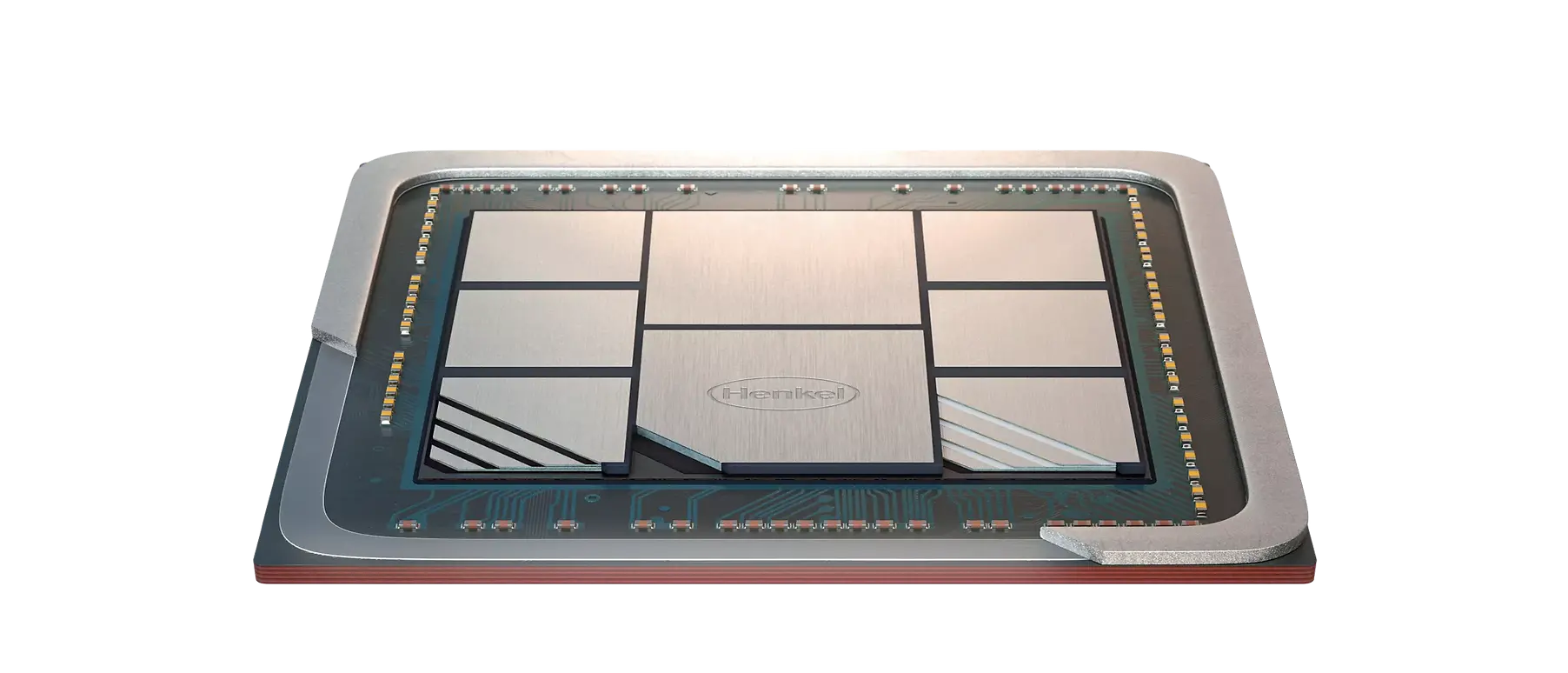

Henkel's advanced packaging portfolio for the semiconductor market

- Thermal Interface Materials (TIMs): Materials that are placed between the package and the lid to move heat away from the device.

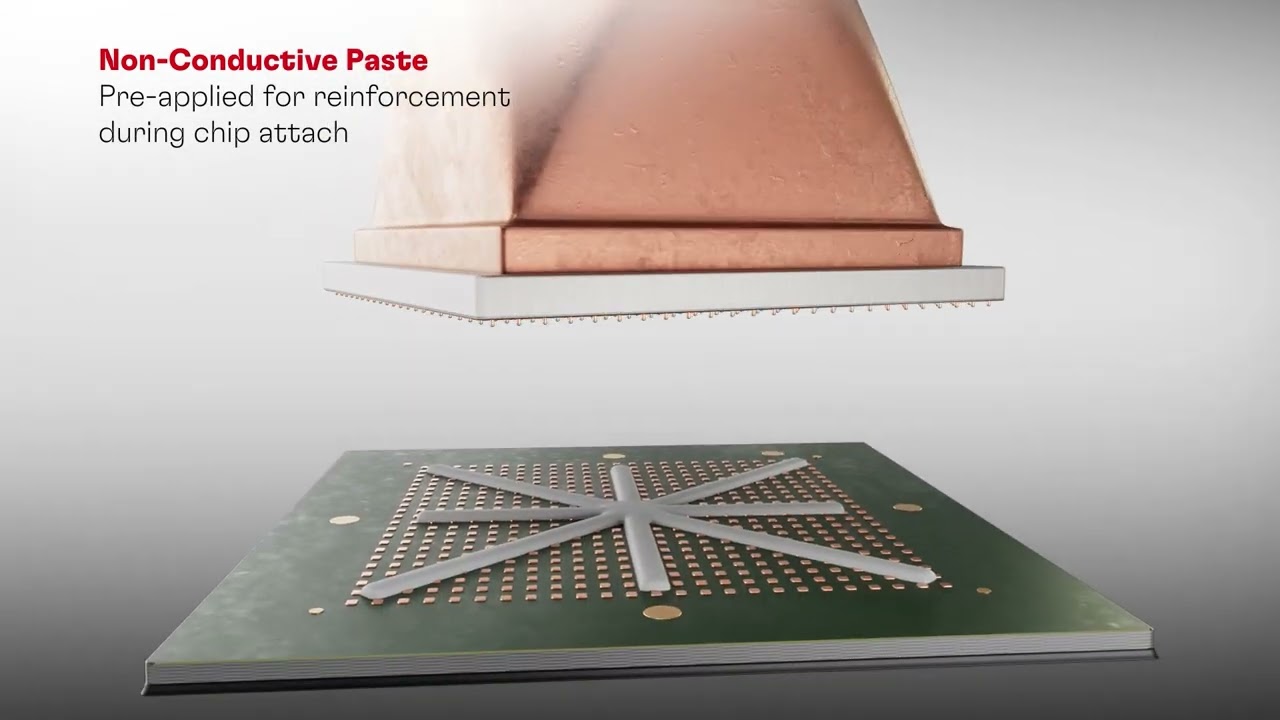

- Underfill technologies: Materials that fill gaps between the silicon die and substrate to protect the chip from damage caused by heat or physical impacts.

- Liquid Compression Molding (LCM): Liquid materials that get compressed to form a solid layer, providing structural support and hermetic sealing to protect semiconductor packages.

- Lid or stiffener attach adhesives: Adhesives used to attach lids or stiffeners to improve large package co-planarity and stability.

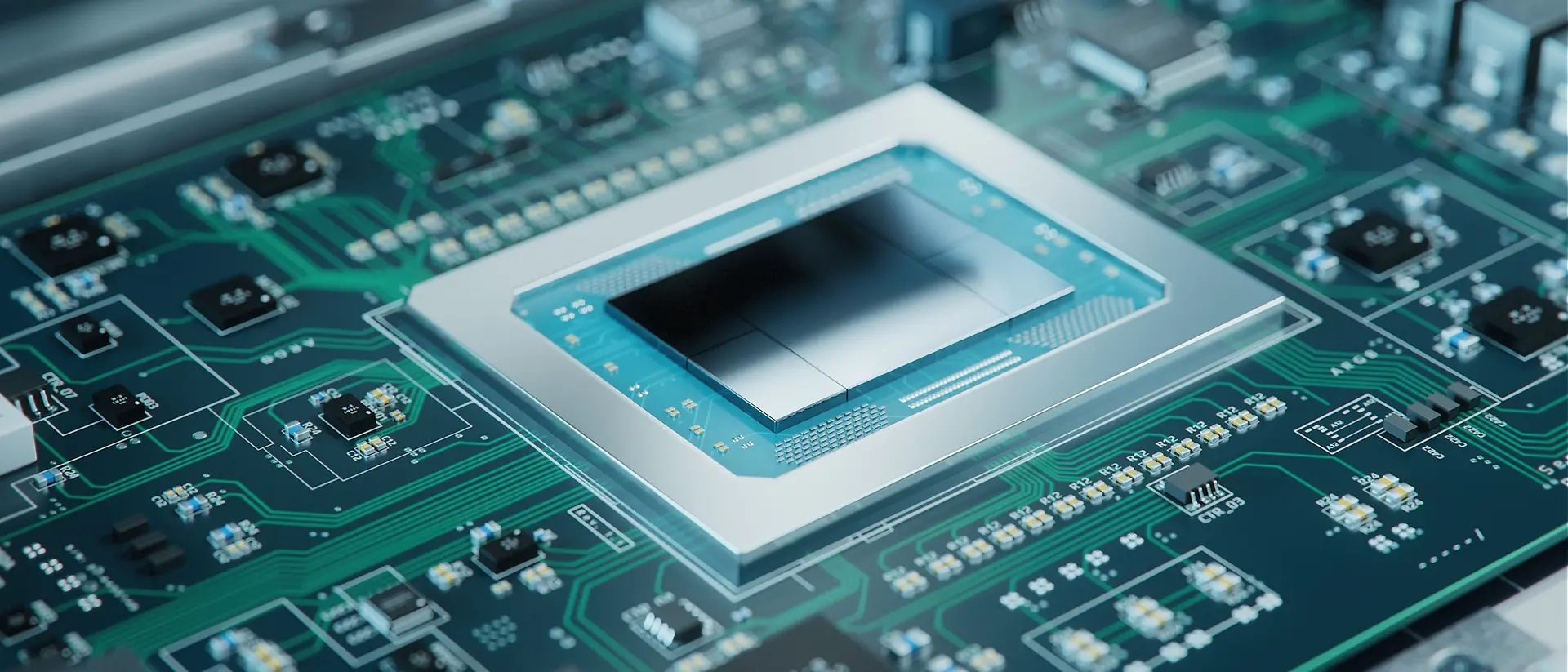

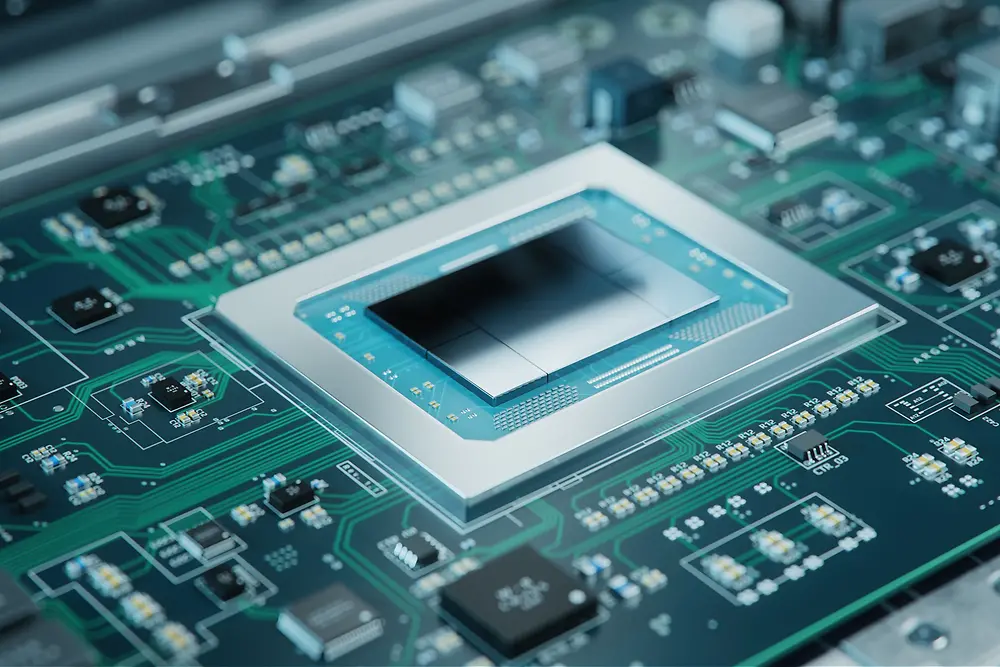

Digital devices are often small – but contain a vast number of complex and specialized technologies. That includes materials that facilitate the flow of electricity to components, strengthen the structure of the device or manage heat in small spaces. It also involves advanced formulations that improve safety or help to reduce greenhouse gas emissions.

Henkel offers a unique portfolio of solutions for the electronics industry. Its teams also share their expertise to help big-name customers in this market to unlock new designs, boost performance and stay ahead of regulatory expectations. The company’s products include Thermal Interface Materials (TIMs), underfill technologies, Liquid Compression Molding (LCM) and lid or stiffener attach adhesives. And Henkel is also a leading provider of materials for semiconductor packaging.