The construction industry is impacting the climate. But the climate impacts constructions too. Sunlight heats up buildings and causes people to switch on air conditioning, which consumes more energy and generates more CO₂ emissions. That means roofs of buildings play a key role in making homes more sustainable – particularly flat roofs in countries close to the Equator that get many hours of powerful sunshine each day.

Henkel offers a wide range of sustainable technologies from its Cool Roof portfolio in selected markets. These paint-like products reflect sunlight, while also waterproofing and insulating buildings. Our latest addition to this range, Fester Acriton Green Shield, is a water-based solution that protects homes against rain and heat – while protecting the environment too. It is proven to reflect more than 85 percent of UV light from the sun and can reduce the surface temperature of a roof by up to 20 degrees Celsius compared to unprotected concrete roofs. That enables significant energy and cost savings for air conditioning, while also ensuring comfortable conditions for people inside.

On top of this, the innovative formula for Fester Acriton Green Shield features a range of additional sustainability benefits. The insulation and reflection performance of this technology, for example, is achieved via a special formula that includes micro-spheres and recycled thermoplastic. The solvent-free and ammonia-free formula also supports the reuse of rainwater in countries that experience water shortages. Rainwater can be collected from the waterproofed roof and used for watering plants, for example.

External surfaces: The key to energy savings

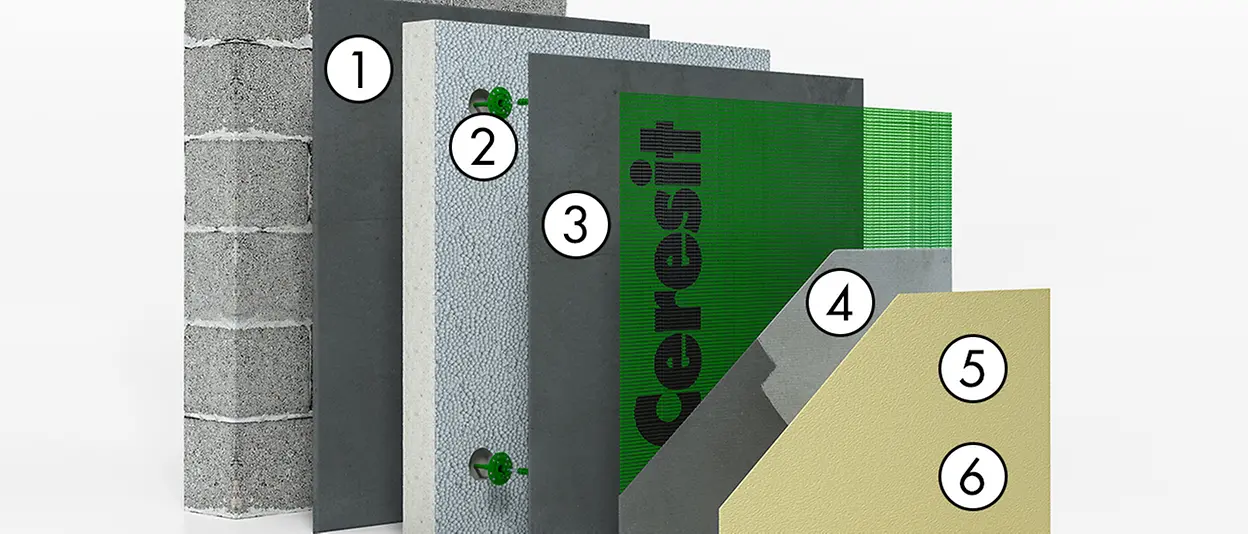

Henkel technologies are keeping roofs cool. They are also doing important work to save energy by insulating the walls of homes and other buildings. Our broad portfolio of External Thermal Insulation Composite Systems (ETICS), which we offer in selected markets, is applied to outside walls and helps to ensure a comfortable temperature inside. In this way, these products cut costs and reduce energy consumption for heating and cooling homes. They also protect the structure against rain, frost and other weather conditions. And they even help homeowners get a better price when they sell properties by boosting the score on the Energy Performance Certificate (EPC), which provides a standardized indication of a building’s energy efficiency.

Recently, scientists developed new and even more sustainable solutions for Henkel’s ETICS portfolio. Ceresit CT 48, CT 49 and CT 54 are façade paints that form the top layer of this building insulation system. 50 percent of the dispersion binder is based on emulsions containing materials that are certified in line with the Mass Balance approach from REDcert. Biomass materials are obtained from the planet’s natural ecosystem and are fully renewable. With this step, we have now swapped 20 percent of the product´s fossil-based materials for more sustainable ingredients that offer a much lower CO₂ footprint.

Importantly, these sustainable technologies also look great on the outside of homes and buildings. Ceresit offers solutions for all types of architectural designs, construction materials and aesthetic preferences. That includes solutions in every possible color and texture, with added functions such as resistance against mold, extra durability or slim designs for crowded spaces. That means homeowners can help protect the planet – while living in style.

- Fixing: Ceresit ZS / Ceresit CT 83 Strong Fix / Ceresit CT 84 Express Plus

- Insulation material: EPS boards

- Reinforced layer: Ceresit ZU / Ceresit CT 85 Flex and Ceresit CT 325 Glass Fibre Mesh

- Priming paint: Ceresit CT 16 Quartz Contact Priming Paint

- Plaster*: Ceresit CT 74 Silicone/ Ceresit CT 76 Solar Protect

- Paint*: Ceresit CT 48 Silicone Self-clean / Ceresit CT 49 Silicone Reno

* Alternative Ceresit plasters: Mineral, Silicate - Silicone, Silicone, Silicate, Elastomeric

Find out more about system details.

The future is now

These bio-based, recycled and low-carbon technologies from Henkel are helping construction companies and craftspeople to embrace more sustainable practices. They are just a few selected examples of our latest innovations that directly respond to insights from the market. Our technical experts work side by side with partners from every step in the value chain to understand the specific challenges they face – and develop high-performance solutions that make a measurable contribution to protecting people and the planet.

That work also requires our teams to anticipate changing technologies, regulations and preferences. Right now, we are exploring ways to reuse the Cross-Laminated Timber and Glued-Laminated Timber elements for another building and reduce its carbon footprint. We are exploring solutions to enable timber construction materials made from a wider variety of wood species. In Europe, we are launching a new fire-resistant range of LOCTITE HB XE adhesives, taking timber construction to new heights of design and safety. In Switzerland we are building an Application Center for Engineered Wood that will provide extensive know-how through customer process simulations, advanced in-house training and debottlenecking to accelerate development and certification. And we are collaborating with thought-leaders to find fresh ways of applying our sustainable technologies to new parts of buildings to expand their positive impact on saving energy, reducing emissions and decreasing waste.

Buildings are more than bricks and mortar. They also have the potential to make a powerful contribution to sustainability. That is what we are working on. And we have already achieved exciting progress.